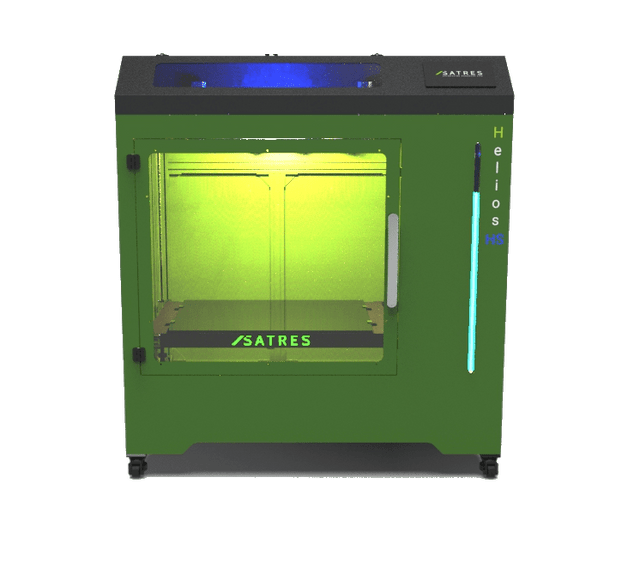

Faster. More precise. Designed to revolutionize 3D printing in orthopedics.

Unmatched Performance & Speed

Prints orthopedic corsets up to 5× faster than traditional 3D printers—completing them in just 6–10 hours compared to the typical 30–40 hours elsewhere.

Achieves blazing print speeds of up to 500 mm/s, dramatically boosting lab throughput.

Cost Efficiency

Offers significantly lower production costs than methods like plaster casting or milling—thanks to reduced material waste, streamlined workflows, and higher productivity.

High-Quality Orthopedic Output

Produces high-precision, durable, and comfortable orthopedic devices using advanced materials and refined printing technology.

Comprehensive Ecosystem

Not just a printer, but a full integrated solution—combining:

Orthopedics-optimized materials

Dedicated software for automated model generation and streamlined design workflows.

Italian Engineering & Support

100% Made in Italy, embodying professional-grade design, reliability, and elegance.

Backed by a dedicated technical support team—plus continuous software updates to keep your lab ahead of the curve.

Technical Highlights

Print Volume: XXL workspace—600 × 600 × 800 mm, ideal for full-size orthopedic devices.

Precision: Delivers fine resolution at 50 µm.

Temperature Management:

Extruders reach up to 400 °C—suited for advanced technical filaments.

Print bed heats up to 90 °C to ensure strong adhesion.

Multi-Material Flexibility:

Supports up to 4 extruders with automatic switching—ideal for multi-material or multi-color prints.

Resilience:

Automatic print resume after power interruptions ensures uninterrupted builds.

Connectivity:

Equipped with Ethernet and 2.4 GHz Wi-Fi for seamless integration into digital workflows.

Build Volume & Weight:

External footprint: approx. 1300 × 950 × 1500 mm

Machine weight: ~250 kg.

Versatile Applications

Supported use-cases span a wide range of custom orthopedic solutions:

Corsets, produced fast and tailored for optimal support.

Braces & Orthoses—lightweight, resilient, and precise for joints like wrists, knees, and ankles.

Custom Helmets, offering a perfect fit and consistent comfort—particularly beneficial for pediatric or therapeutic applications.

Orthopedic Insoles, manufactured with millimeter-level accuracy to enhance weight distribution and foot support.

Prosthetics, personalized for individual patients—combining functional design, comfort, and autonomy-enhancing detail.

Summary

The Helios HS Ortho redefines 3D printing standards in orthopedics by delivering industry-leading speed, precision, and adaptability. Its expansive build volume, advanced thermal control, automated extrusion management, and resilient design offer unmatched workflow efficiency. Supported by Italian engineering and round-the-clock assistance, it transforms orthopedic labs into high-performance, patient-focused production environments.

Read more less