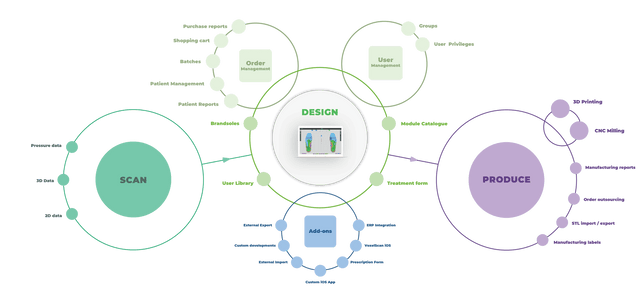

Orthotic and prosthetics CAD & workflow software is the digital backbone of modern O&P clinics, enabling practitioners to design, customize, and manage the production of orthoses and prostheses with accuracy and efficiency. These platforms integrate patient scanning, 3D modeling, and design tools to create highly personalized devices, whether for 3D printing or CNC milling.

In the clinic, CAD software allows orthotists and prosthetists to digitally modify limb or body scans, adjust alignment, and fine-tune device geometry without the mess and limitations of plaster. Workflow software then manages the entire process—from design to manufacturing—ensuring seamless communication between scanners, design stations, and production equipment.

By combining precision with efficiency, orthotic & prosthetic CAD and workflow solutions reduce turnaround times, minimize material waste, and enable easy reproduction or adjustments of patient devices. This digital approach improves patient outcomes through better-fitting orthoses and prostheses, while streamlining operations for clinics adopting both additive (3D printing) and subtractive (milling) manufacturing technologies. orthotics prosthetics CAD software.